Welcome to Get Star Weld!

Welcome to Get Star Weld!

05 Jul, 2023

If you're involved in metalworking or fabrication, you probably understand the importance of a reliable cutting torch. The air-cooled plasma cutting torch is a versatile tool that has gained popularity in various industries for its efficient cutting capabilities. In this article, we will explore the ins and outs of the air-cooled plasma cutting torch.

A plasma cutting torch is a handheld tool used in metal fabrication and welding processes. It generates a high-temperature plasma arc that melts and cuts through electrically conductive materials, such as steel, aluminum, and copper. A plasma cutting torch utilizes compressed air or other gases to create a focused and powerful plasma stream, enabling precise and efficient cutting.

When an air-cooled plasma cutting torch is activated, a high-frequency electrical arc is established between the electrode and the workpiece. This ionizes the compressed air, transforming it into plasma. The plasma reaches temperatures of up to 30,000 degrees Fahrenheit, melting the metal in its path. The high-velocity gas flow blows away the molten material, creating a clean and precise cut.

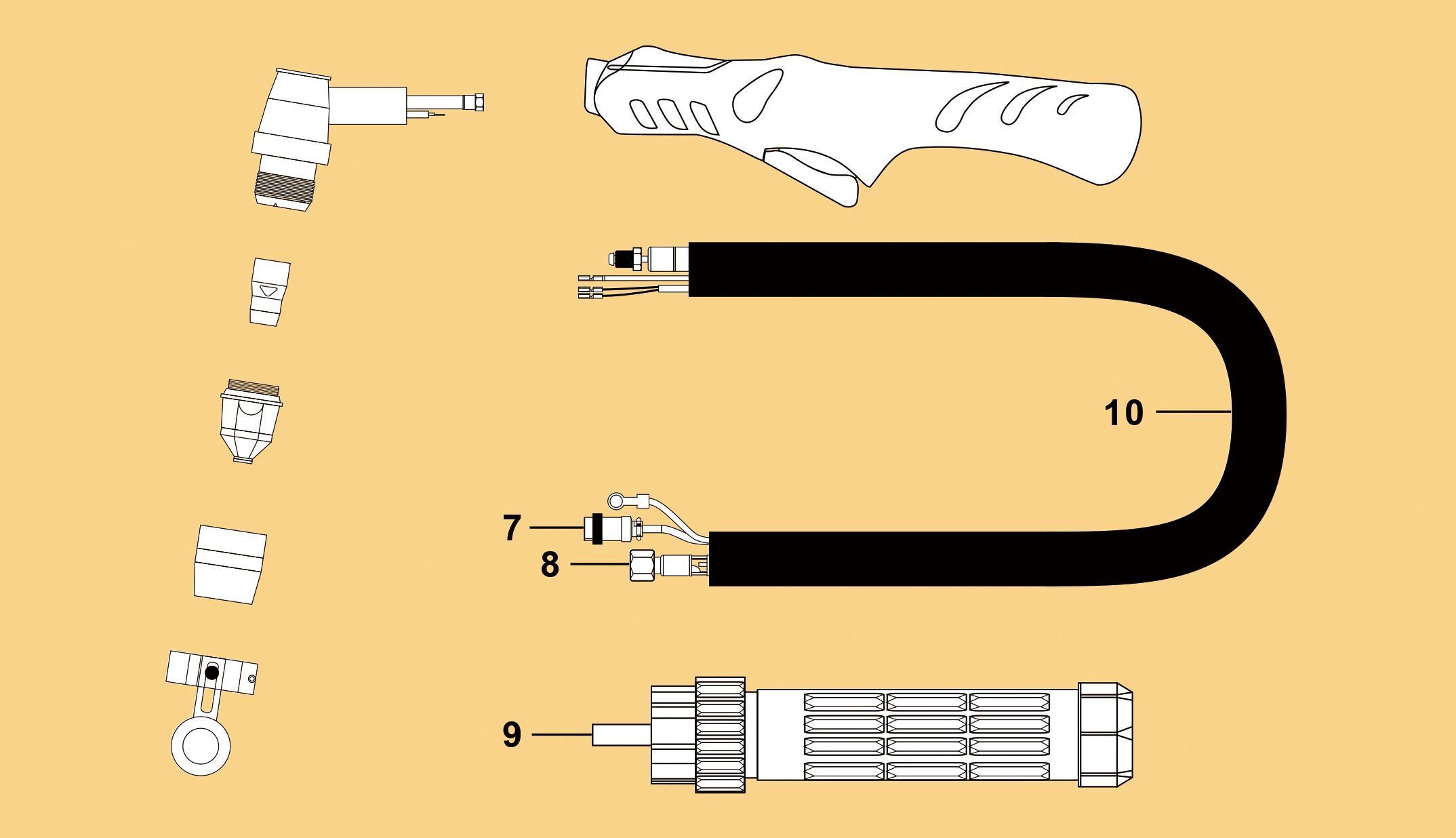

An air-cooled plasma cutting torch mainly consists of the following main components:

The torch handle is the part held by the operator during cutting. It is ergonomically designed for a comfortable and stable grip, allowing precise control over the torch.

The electrode is the negatively charged component of the torch. It generates the plasma arc and directs it toward the workpiece.

The nozzle surrounds the electrode and helps in focusing the plasma arc. It also acts as a shield, protecting the electrode from molten metal and extending its lifespan.

The swirl ring is located between the electrode and the nozzle. It controls the flow of gas and creates a swirling motion that stabilizes and enhances the plasma arc.

The shield cap is a removable cover that further protects the electrode and nozzle. It also shapes the plasma arc for improved cutting performance.

Various consumable parts, such as electrodes, nozzles, swirl rings, and shield caps, need regular replacement to maintain optimal cutting quality and efficiency.

Portability: Air-cooled plasma cutting torches are lighter and more portable compared to their water-cooled counterparts, making them ideal for on-site or remote cutting applications.

Cost-Effectiveness: Air-cooled torches are generally more affordable and require less maintenance than water-cooled systems, resulting in cost savings over time.

Ease of Use: With their simple design and fewer components, air-cooled torches are easy to operate and maintain, making them suitable for beginners and professionals alike.

Lower Cutting Capacity: Air-cooled torches are typically limited in their cutting capacity compared to water-cooled torches. They are more suitable for thin to medium-thickness materials.

Reduced Electrode Life: The higher operating temperatures of air-cooled torches can lead to faster electrode wear, requiring more frequent replacements.

Cutting Capacity: Ensure that the torch can handle the thickness of the materials you work with.

Consumable Availability: Check the availability and cost of consumable parts to ensure they are easily replaceable.

Torch Compatibility: Verify that the torch is compatible with your plasma cutting system and a power source.

Air-Cooled Plasma Cutting Torch

To maintain optimal performance and longevity of your air-cooled plasma cutting torch, follow these tips:

If you encounter issues with your air-cooled plasma cutting torch, consider the following troubleshooting tips:

When using an air-cooled plasma cutting torch, prioritize safety by following these precautions:

In conclusion, air-cooled plasma cutting torches are versatile tools that enable efficient and precise metal cutting. Their portability, cost-effectiveness, and ease of use make them popular among professionals and enthusiasts alike. Get access to a wide range of air-cooled plasma cutting torches and more cutting tools at GET SATR WELD. Explore our selection and find the perfect tool for your metal-cutting needs.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse viverra mauris eget tortor.